Rely on our mold design expertise.

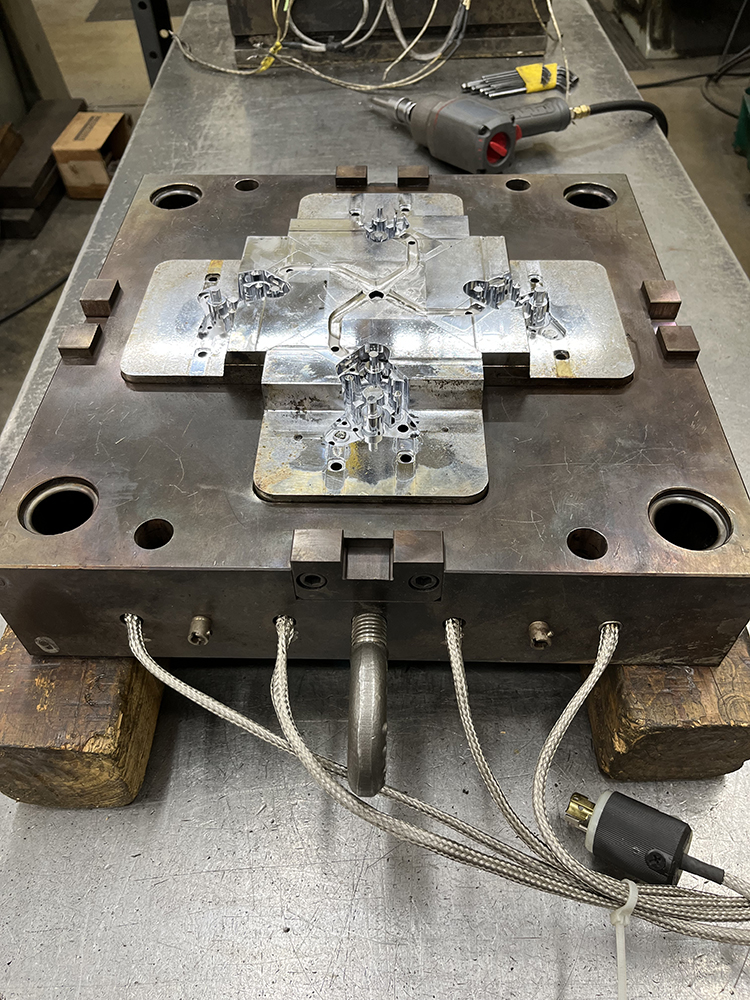

It all begins with a robust mold design. Because without a good mold, there is no way we could manufacture the high-quality plastic parts synonymous with Van Norman Molding. In fact, many of our high-capacity molds deliver more than 15 million parts per year.

Focusing first on design for manufacturability (DFM), a robust part design is generated and lets us provide a solid mold design, which gives our customers the high quality plastic parts they require. Our cross-functional design team, made up of team members from our engineering, tooling, manufacturing and quality assurance departments, oversee every mold from design to build to prototype to production.

With our in-house mold shop, we have complete control over the entire process, including steel selection, heat treatment, machining, polishing and plating.

From the simplest molds to complex, multi-cavity high-production molds, we can guarantee our new molds for a minimum of ½ million cycles and more.

Quality and maintenance are key.

To ensure maximum mold life and the best possible performance, most of our molds are built to SPI Class 101, 102, and 103 standards. Our “Class A” production molds also feature:

- Hardened tool steel cavities and cores

- Surface coatings for improved part release and mold wear

- Key mold components are made from hardened tool steel

- Guided ejection

- Parting line locks

- Regular, preventative maintenance, ensures a long tool life