We focus on making the plastic molding process even better.

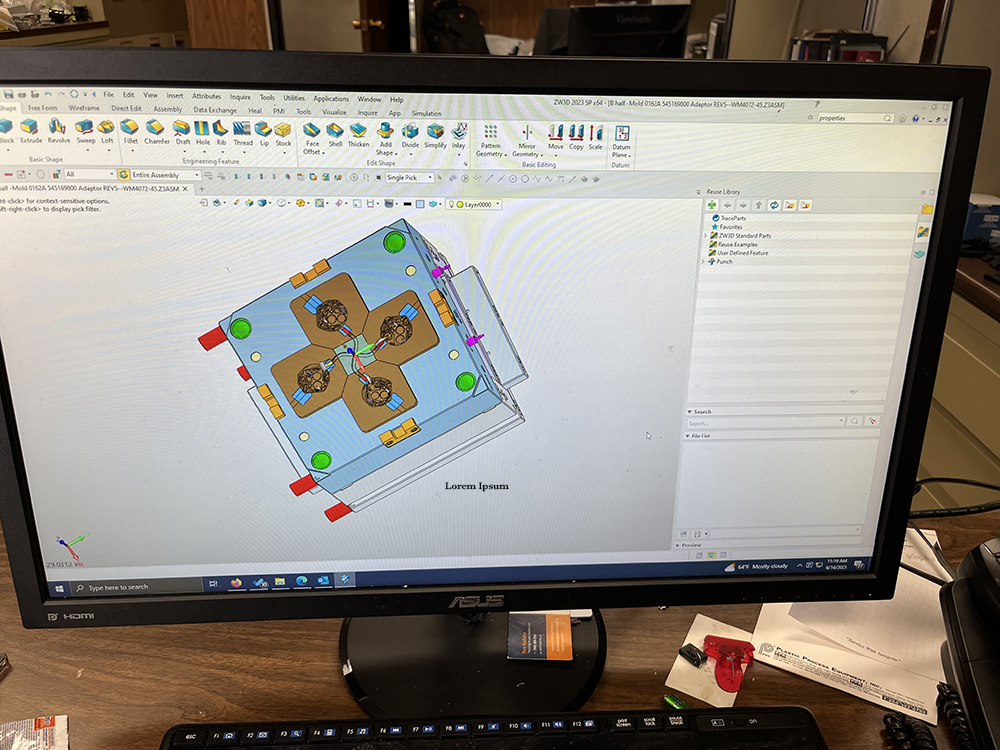

At Van Norman Molding, we’ve optimized the entire plastic molding process. For every project, we use our Quality Planning Protocol. You’ll work with one of our cross-functional teams consisting of team members from our engineering, tooling, manufacturing, and quality assurance departments. They review your part design utilizing the design for manufacturability (DFM) process, help select the appropriate molding process, choose the right materials and then design and build the mold.

Our DFM process helps us ensure:

- Part quality and durability

- Cost control so you get the best possible value

- Avoidance of potential mistakes and problems

- Shorter lead times

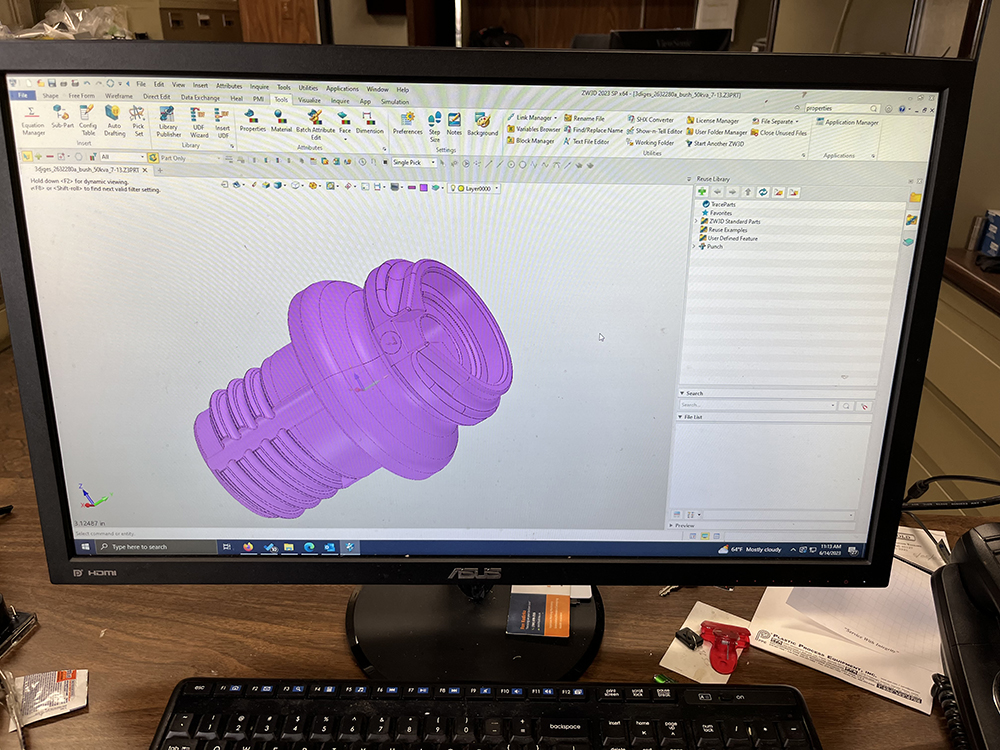

Overseeing part design for manufacturability and quality.

We help our customers create the best possible part design for application, performance and manufacturability. Most customers supply a complete design. And others want us to help improve a part design from an existing or similar part. In any case, our technical experts will help make sure the final design is robust so your parts will perform to your – and our – uncompromising standards.

Our technical capabilities include:

- More than 85 years of plastic mold making, design and manufacturing experience

- Fully equipped CAD workstations

- 3D design software

- Gage design

- Finite Element Analysis (FEA) and Moldflow Analysis

- PPAP’s are supplied